SAYEAH is a trusted global leader in high-end thermoforming technology with over 20 years of experience. We design advanced machines for the efficient mass production of plastic cups and disposable bowls, including drinking, jelly, yogurt, and coffee cups. Our technology processes a wide range of thermoplastics, such as PP, PE, PVC, and PET, handling materials from 0.15mm films to 2mm sheets with precision and consistency.

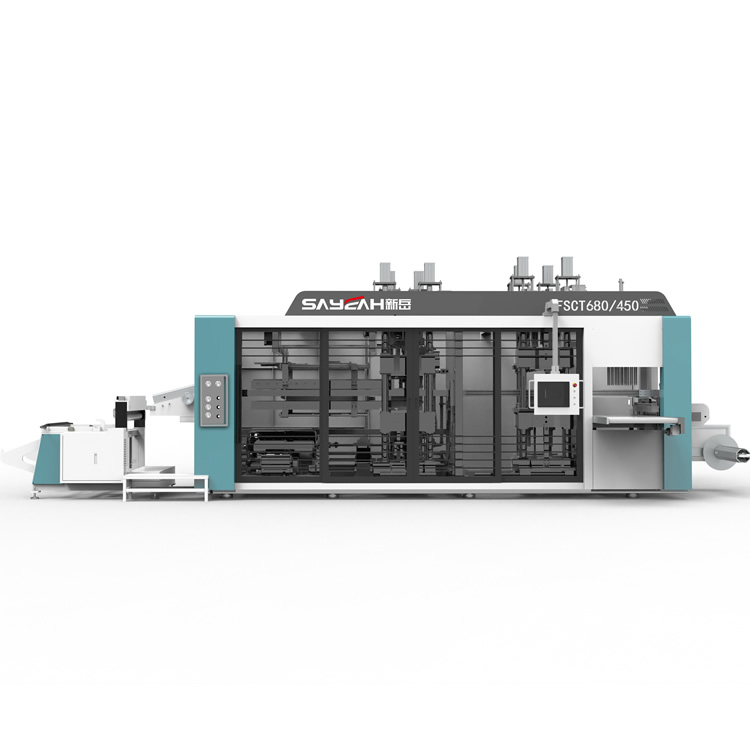

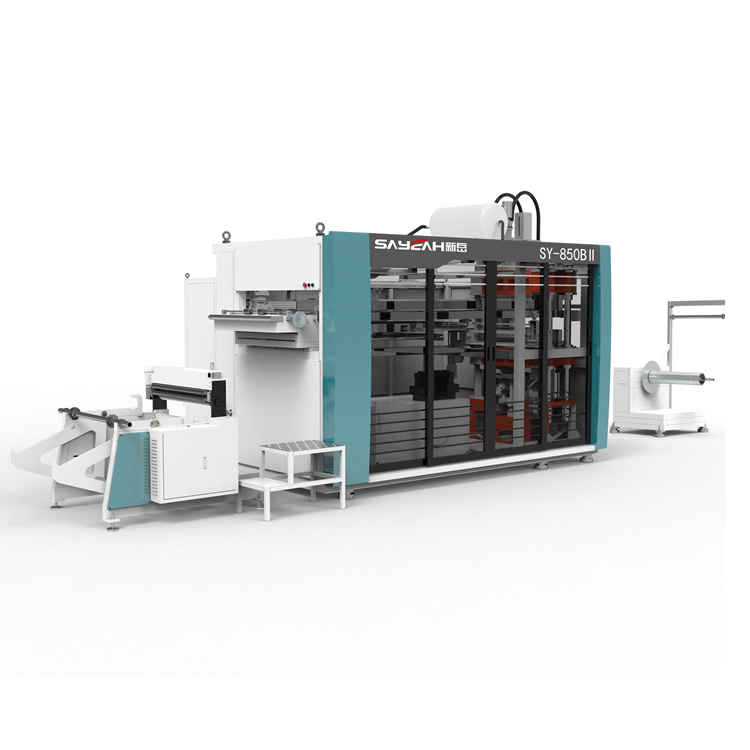

The SAYEAH Plastic Cup Making Machine efficiently produces a wide variety of plastic cups and bowls in any size or shape. This process heats and softens the plastic sheet, then uses vacuum or pressure molding to accurately replicate the shape of the mold, ensuring high consistency and precision in the final product.

This series mainly used for making different kinds of plastic cups, such as water drinking cups, jely cups, yoghurt cups, coffee cups. lt can also make flower pots, disposable bowls, lids, plates, trays and etc.

Max.Forming Area: 650/320

Max.Forming Height And Depth: ≤135 mm by robot, ≤170mm by blowing

Max.sheet width: 690

Built with durable components and robust construction, the Automatic Plastic Cup Making Machine delivers reliable performance, minimizing downtime and maintenance requirements.

Max.Forming Area: 750/450

Max.Forming Height And Depth: ≤140 mm by robot, ≤240mm by blowing

Max.sheet width: 780

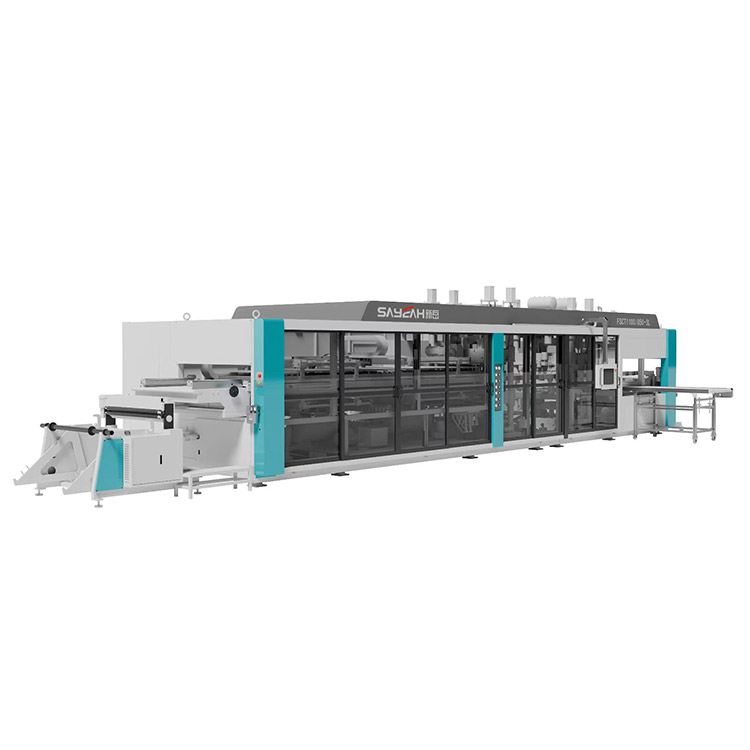

European design, suitable for diversified production lines, Safe, efficient, energy-saving and hygienic. Unwinding station electric lifting, double roll holder. Operator-friendly HMl, and the system has the function of remote connection.

Max.Forming Area: 680 / 450

Max.Forming Height And Depth: 140/140

Max.sheet width: 720

This Thermoforming Machine features a European design, encompassing comprehensive functions that cater to diverse production lines, prioritizing safety, efficiency, energy conservation, and hygiene. Its unwinding station boasts electric lifting and a double roll holder, facilitating the effortless loading of rolls weighing up to 1 ton by a single operator.

Max.Forming Area: 820 / 650

Max.Forming Height And Depth: 150/150

Max.sheet width: 860

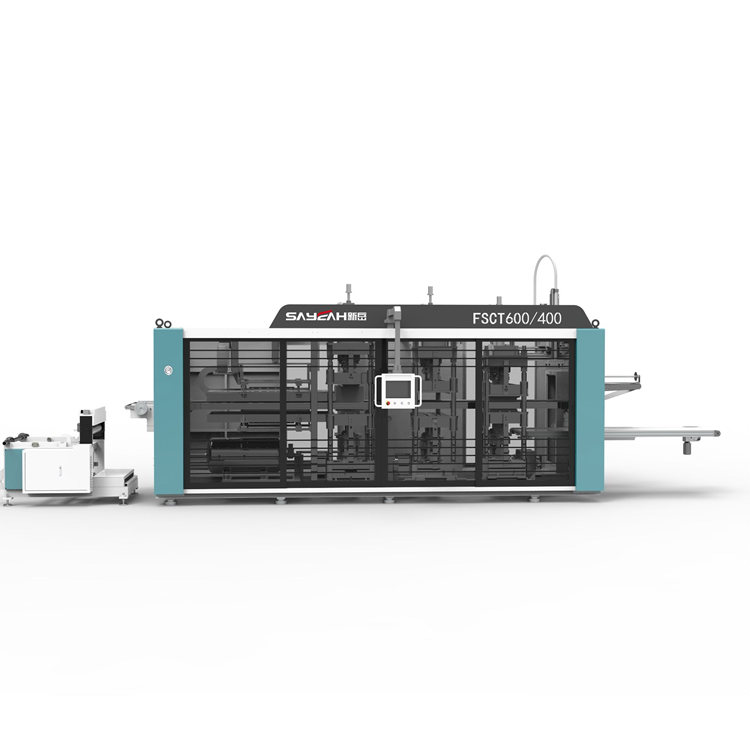

This machine is specially designed for making different kinds of lids for plastic/paper cups, mini soup spoons, trays formedicine and etc.

It feeds cup on level and adopts corona pre-treatment, mandrel UV curing, so printed pattern is clear and real. Main motor mounted with three-phase frequency conversion speed adjust, timing belt drive, stepless speed regulation, functions steadily without noise. Convenient to adjust quantity of ink and pressure of ink distributing roller, and the ink supply is ideal. When fix forme, locating spring can automatically tighten, and it is easy to load or unload the forme, as well as chromatography. Printing cylinder and forme roller assembled with cantilever are easy to clutch and adjust pressure.

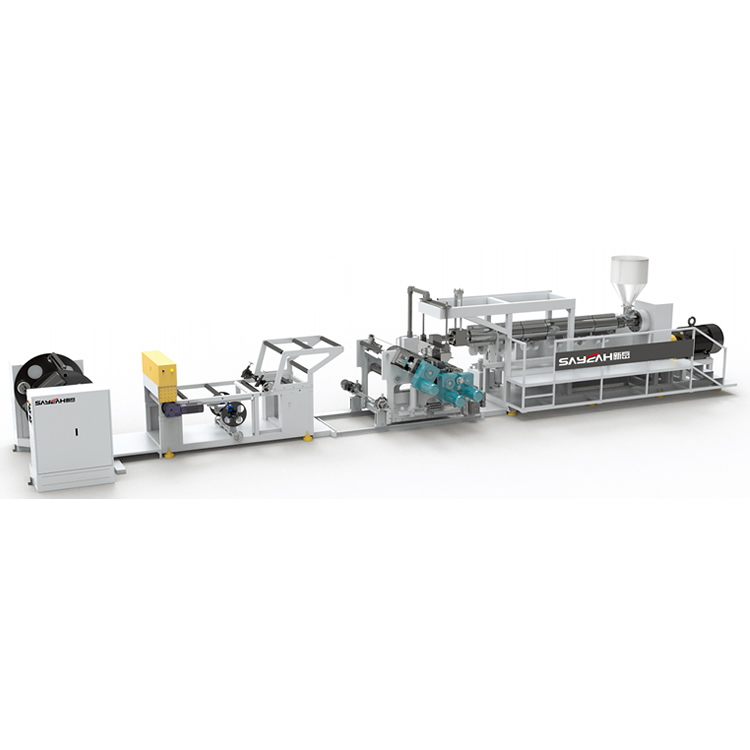

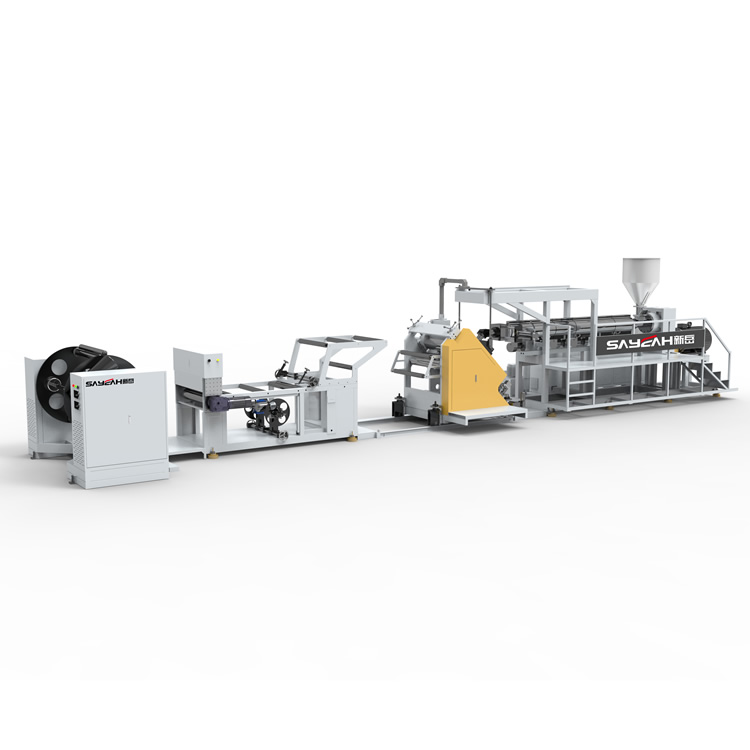

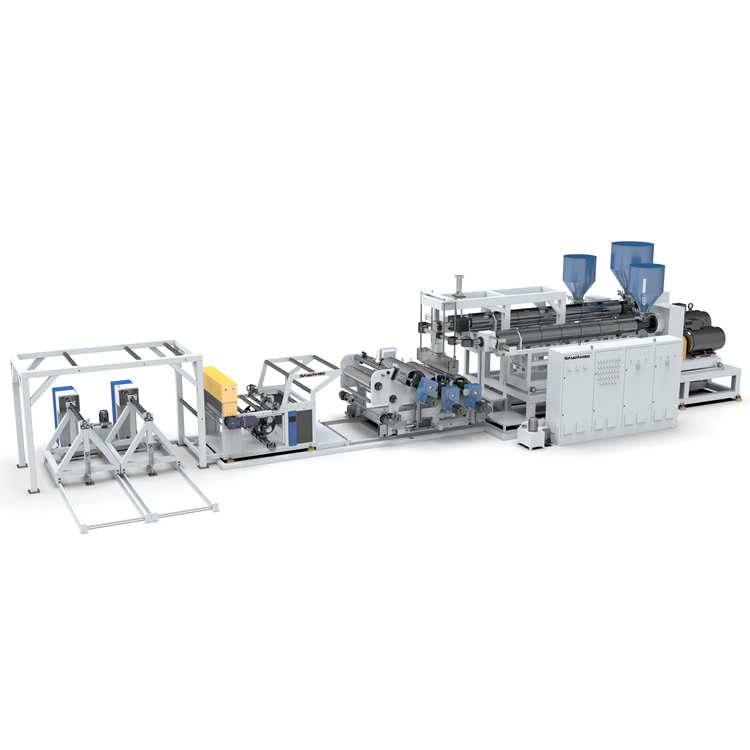

This series is designed to produce mono-layer PP/PS/PE/HIPS plastic sheet, which is used for making disposable water drinkingcups, ice-cream cups, yoghurt cups, lids, trays,plates and etc.

lt’s one of the most advanced production lines with matured technology and stability in China.Compared with other samekind equipment,it’s over 30% higher in overall efficiency.Line is suitable for PS,PPPE sheet as well.

This series is designed to produce mono-layer PP/PS/PE/HIPS plastic sheet, which is used for making disposable water drinkingcups, ice-cream cups, yoghurt cups, lids, trays,plates and etc.

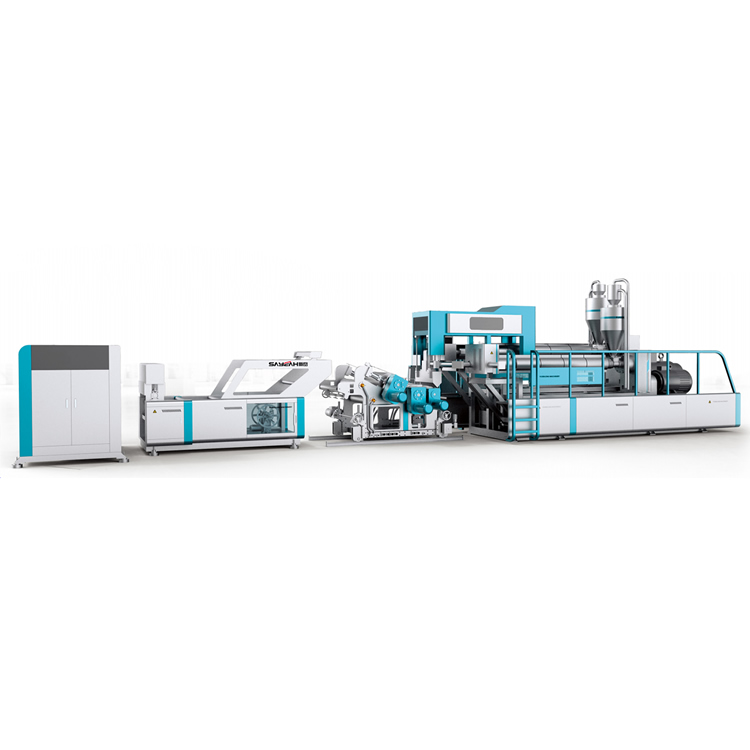

This machine mainly for producing PP/PS/PE double-layer plastic sheet,which is used for making disposable water drinkingcups, ice-cream cups, yoghurt cups, lids, dishes, plates and etc.

The electric lifting feature of the unwinding station, coupled with the double roll holder, enables effortless loading of rolls weighing up to 1 ton by a single operator, enhancing productivity and convenience.

Max.Forming Area: 600/400

Max.Forming Height And Depth: 80/40

Max.sheet width: 640

Equipped with advanced automation technology, the Automatic Thermoforming Machine streamlines the production process, reducing manual intervention and increasing production efficiency. With its high-speed operation, the machine can manufacture a large volume of plastic cups within a short timeframe, ensuring timely delivery and meeting market demands.

Max.Forming Area: 850/550

Max.Forming Height And Depth: ≤140 mm by robot, ≤180mm by blowing

Max.sheet width: 870

This series mainly used for making different kinds of plastic flower pots, trays, plate, bowl, cups and other plastic packaging products.

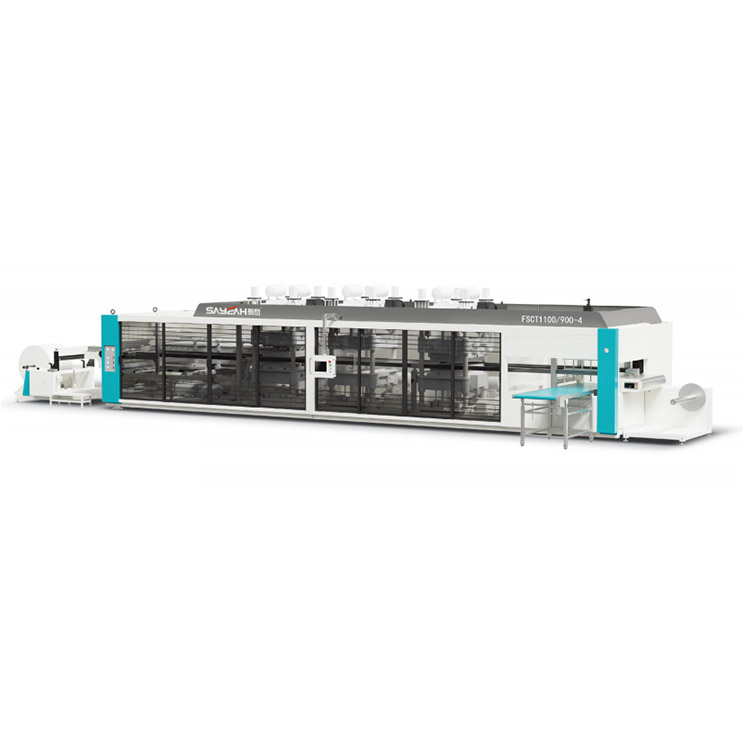

Max.Forming Area: 1100 / 850

Max.Forming Height And Depth: 145/125

Max.sheet width: 1130

World's Largest Multi-Station Thermoforming machine

Sayeah People will continue to work hard as always to build world-class Thermoforming machine, Let the world love Sayeah Machinery.

Add: Sunlou Industrial Zone, Pingyang County, Wenzhou City, Zhejiang Province, China

Whatsapp & Wechat & Mob: 0086-18358758581

General Manager : Linda Lin

Email: sales@fujinlong.com